EasyBases for Professionals

EasyBases for Professionals is a partnership opportunity offering the chance to add a competitive edge and extra income stream to your business. With a cost to customer sitting somewhere between wooden platform and heavy duty timber bases, EasyFrames provide an extra choice of material and levelling options. EasyFloors add another set of options and supported structures types, extending your scope further.

Your skill and experience will determine the base you require, we are not selling dreams of a frame to sit safely in a bog!

Work on gardens and outside areas spans many fields of expertise, with many specialists covering more than one. EasyBases provide Designers, Landscapers, Building Contractors, base installation specialists and event/exhibition contractors with a set of versatile building blocks to choose from.

For quality, value and convenience, EasyBases fit the bill, here are some reasons;

- Adaptable: Ideal for locations where pouring concrete is either impractical, costly, or simply impossible due to access limitations (e.g., narrow garden paths, access through the house).

- Easy to Assemble: Our aluminium frames are lightweight, strong, and designed for easy assembly with basic tools, allowing you to complete projects faster and with less hassle.

- Versatile: Use EasyBases instead of existing methods or to complement them, expanding your design and implementation options.

- Innovative: The design of the foot mounting assembly allows for alterations to height and load distribution at point of and after installation.

- Adjustable: EasyBases can be adjusted precisely. Easybase feet can each be adjusted up or down, relocated to another point on the frame or additional feet can be added.

- Portable: Standard offerings of tanalised wood and modern modular structures are advertised to last for 30-50 years. Anodised Aluminum EasyBases provide the option to move both base and structure for relocation on an existing or new site.

- Eco-Friendly Option: Aluminium is a sustainable material, making it an attractive choice for environmentally conscious customers. In addition, the longer a structure and base lasts, the lower the impact from manufacturing and waste processes. EasyBases are matching the industry trend towards extremely long-lived structures by using corrosion-free, anodised Aluminium.

-

Diversification: Many of our customers provide a range of products and services. EasyBases add to the diverse range of materials and construction methods available today.

Common sense and experience will dictate when and how best to use EasyBases for your customer’s projects. Make sure you keep up with all offerings on the market today by contacting us on 01386 430121 or sales@easybases.co.uk to see how we can assist.

Why Partner with Us?

- Additional Revenue Stream: By offering our aluminium frames alongside your concrete and other services, you can create a new revenue stream while expanding your business offering.

- Simple Set-Up: Our system allows you to build a solid frame in a fraction of the time it takes to pour and set a concrete base.

- Flexibility: The frames can be used in a variety of sizes and configurations, including some non-standard, so perfect for both small and large projects.

- Support: EasyBases for Professionals; Our partners will be offered the choice to test new developments to EasyBases before general release. We also offer detailed guidance and advice to help you get the job done quickly and efficiently. By the same merit we are always happy to hear feedback from you about suggested innovations, novel installations and of course photos of your completed projects!

Ready to Get Started?

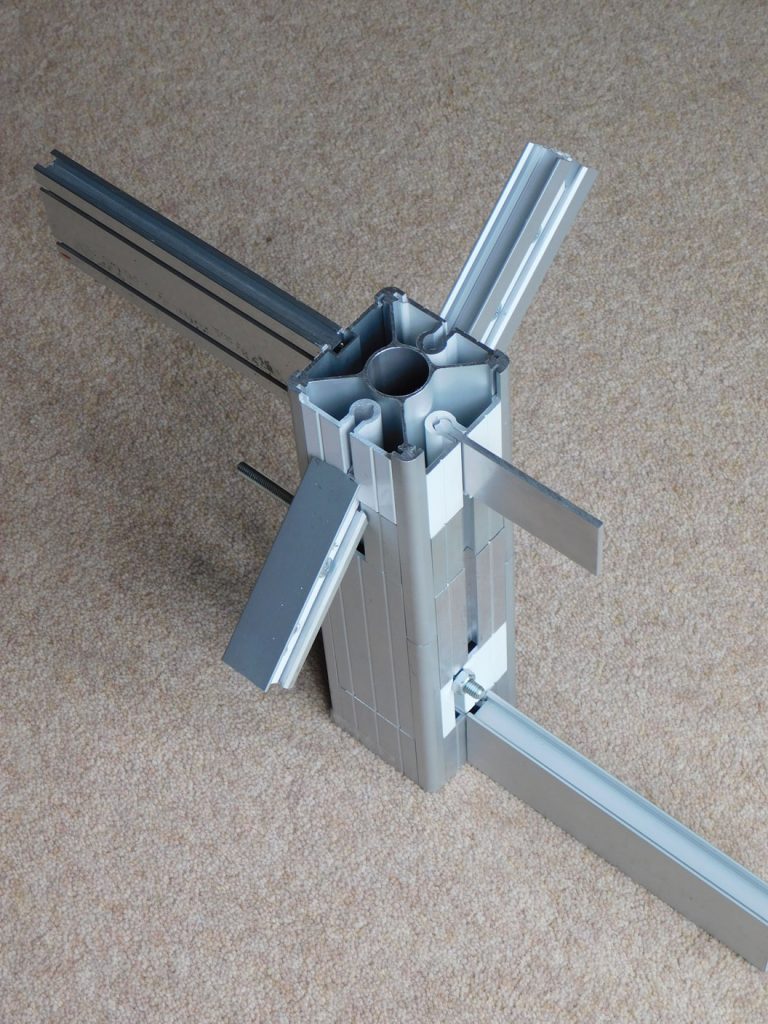

Installation of EasyFrames and EasyFloors has been designed to allow assembly with minimal complexity and tools.

This means;

- No drilling to fix bolts at any point on the frame.

- Cross-beams that slot into riveted supports.

- Pre-fitted hex bolts to fix corners.

- Tiles that slot perfectly into place.

Tools required;

- to assemble EasyFrames – 4mm Hex key

- to assemble EasyFrames with adjustable feet – 4mm Hex key and M12 spanner and or adjustable pliers.

Base Build Steps

- Determine required dimensions, whether levelling feet or your own means of levelling will be used and place your order. We will be happy to advise on any aspect of your order.

- Prepare base location for your desired frame configuration. This could be concrete, soil, ground screws, patio, roof terrace, bricks(!)…

- Follow from ‘a’ to ‘c’ as your installation requires.

- If laying frame only; Attach corner connecting pieces, connect frame and support bars, place frame and install structure.

- If laying frame and levelling feet; As above with the addition of the feet assemblies during frame assembly. Once frame is in place, adjust to level desired using spanner or pliers (for example, hot tubs may require an angle for run-off). If at all required, make a final adjustment to feet after structure is in place.

- If laying frame and floor tiles, with or without feet; Once frame is assembled and in-situ, simply lay tiles into assembled frame. Mind your fingers!

It is that easy!

Get in touch with us today to learn more about how these innovative frames work, and how you can integrate them into your existing services or product ranges.

EasyBases can be combined with our existing range of Aluminium products from the clicK and Geneero ranges linked below. Geneero and clicK Shelving frameworks, a part of Hammond Industries